Shells for the M-203 replica

Started with some 6061 thick wall, 1-1/4 ID 1-3/4 OD and some 1-1/4 6061 round bar

Vise pressed the bar into the end of the pipe

After pounding and squeezing, this is as far in as they would go. Put a pipe on the vise handle, (mistake) may have damaged the leadscrew/nut assembly. Have to get a real press one of these days. Anyway, very tight fit, donít think Iíll have any separation problems with the relatively low pressure levels Iíll be working with.

Turned the end flat and true

Center drilled, Primer pocket and flash hole. This is where a 109 pc drill set comes in handy, can hit primer diameter within a couple thou.

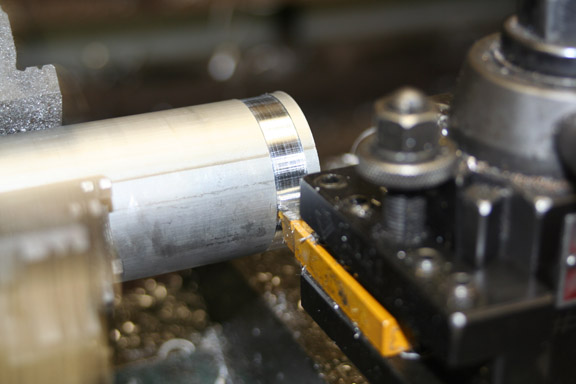

Turned the first 3/8" in front of the rim next, cutting the whole width all at once.

†This is a very noisy, chattery operation, but I wanted to get several of these knocked out and it seemed the quickest way to turn down a starting point.

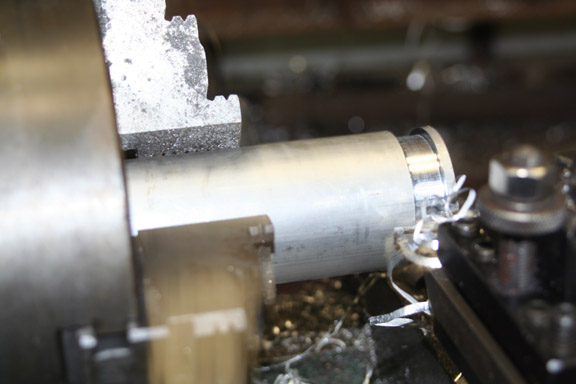

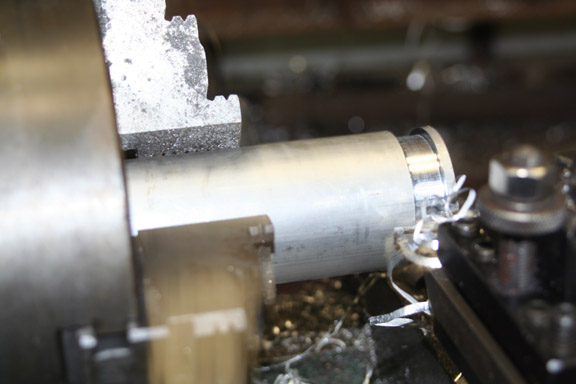

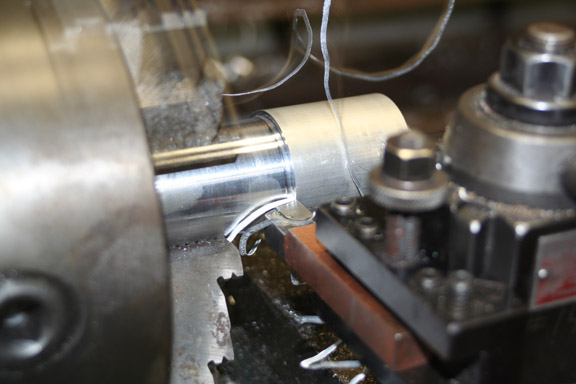

Next cut the rest of the shell. This is why the flat groove picked me up some time.

†Able to make one pass with a large cutter.

Better put the camera down before the tool runs into the chuck!

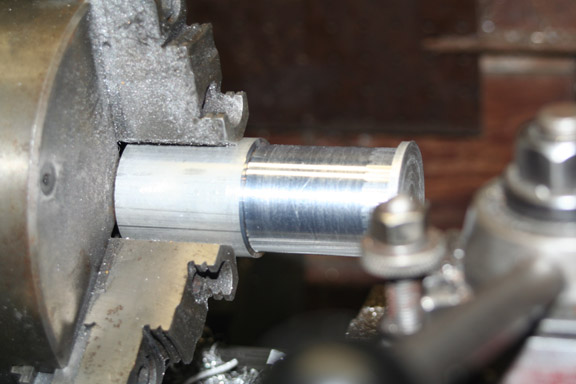

Reverse shell, true up, and finish cut. Good thing the recesses in the back of the jaws clear the rim.

Any machinist will tell you this isnít the most accurate way to do this, but the tolerance isnít that critical, so I sacrificed a little trueness for production.

Next I removed some of the material from the inside, taking the wall down to around 1/16Ē

And Wa-La!

Made most of them large pistol, tried one shotgun. Pistol primers easier to seat/ unseat. All go off with a bang.

Next Iíll fill up with some pyro compounds. After seeing what happens when a salute detonates inside a mortar tube, probably stay away from flash compounds!!! Think I'll stick to stuff that wonít kill me if things donít go as planned. Also going to turn an adapter for marine flares (12 GA)